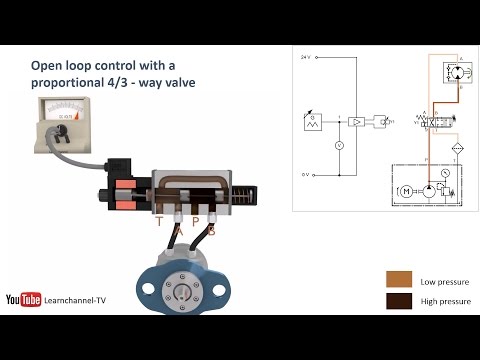

The flow of a simple control valve, as you know, is typically limited to fully closed, fully open, or fully switch to a new flow path. These types of control valves are of simple design and you would use them for binary actors. But in the field of automation, you would have higher demands, like controlling the revolution speed of a hydraulic motor or the position of a linear piston. Proportional control valves offer a solution to the complexity of these demands. Mechanically proportional valves appear similar to their binary counterparts, but the big difference is the way the solenoids work with an electrical control signal, which can be a variable voltage or current. The proportional solenoids can produce a variable force to shift the spool against the counteracting spring. A sloping arrow in the operational symbol indicates this proportional force to avoid flow lack due to spool overlap. Most manufacturers cut V notches into the spool that allows the same flow to pass as soon as the spool moves. Most of these valves are used in open loop systems to smoothly accelerate or decelerate, for example, a hydraulic motor or to move a cylinder to any position. The disadvantages are the rather big reaction time, the switching hysteresis, and a relatively high electrical power consumption. Another type of hydraulic valves are the so-called servo valves, developed in the 1940s. These servo valves operate with high accuracy, small reaction time, a smaller switching hysteresis, and less power consumption. The main difference between proportional and servo valves is that servo valves have feedback of the spool, which can be used for an internal signal for the controller to adjust the valve itself. Oil from the pump inlet is tapped through filters, passes both ends of the spool and the control lines,...

Award-winning PDF software

16 mechanical ventilation Form: What You Should Know

Forms and Procedures for Mechanical Ventilation — Part 3 — B1.8. A.1. B; B1.8. A.1. C: Air Management Part 3-B1.8.1. Air Management 1. Indoor air quality will be improved if at least 25% of the air is purified. All parts of the building, such as indoor flooring and furniture, shall be pushed to the exterior where outdoor air can be exhausted by the building. For this purpose, air shall be drawn in from outside and excluded from indoor rooms.2. Indoor air quality is better maintained if at least 75% of the outdoor air is purified by purifiers. The outdoor air purifier should operate at a temperature of 35–45 °F to purify air to a level where it can be discharged to open air for outdoor use. It must contain the following criteria: 1) A pressure of at least 40 psi (0.9 MPA) with no restriction on the air flow rate; 2) A pitch of at least 2.3 HP air flow per square inch at a rate of 1.5 HP/inch per hour; and, 3) The purifier should be compatible with indoor plumbing (e.g., plumbing in bathrooms etc.)3.

online solutions help you to manage your record administration along with raise the efficiency of the workflows. Stick to the fast guide to do aU Form 16, steer clear of blunders along with furnish it in a timely manner:

How to complete any aU Form 16 online: - On the site with all the document, click on Begin immediately along with complete for the editor.

- Use your indications to submit established track record areas.

- Add your own info and speak to data.

- Make sure that you enter correct details and numbers throughout suitable areas.

- Very carefully confirm the content of the form as well as grammar along with punctuational.

- Navigate to Support area when you have questions or perhaps handle our assistance team.

- Place an electronic digital unique in your aU Form 16 by using Sign Device.

- After the form is fully gone, media Completed.

- Deliver the particular prepared document by way of electronic mail or facsimile, art print it out or perhaps reduce the gadget.

PDF editor permits you to help make changes to your aU Form 16 from the internet connected gadget, personalize it based on your requirements, indicator this in electronic format and also disperse differently.

Video instructions and help with filling out and completing Form 16 mechanical ventilation